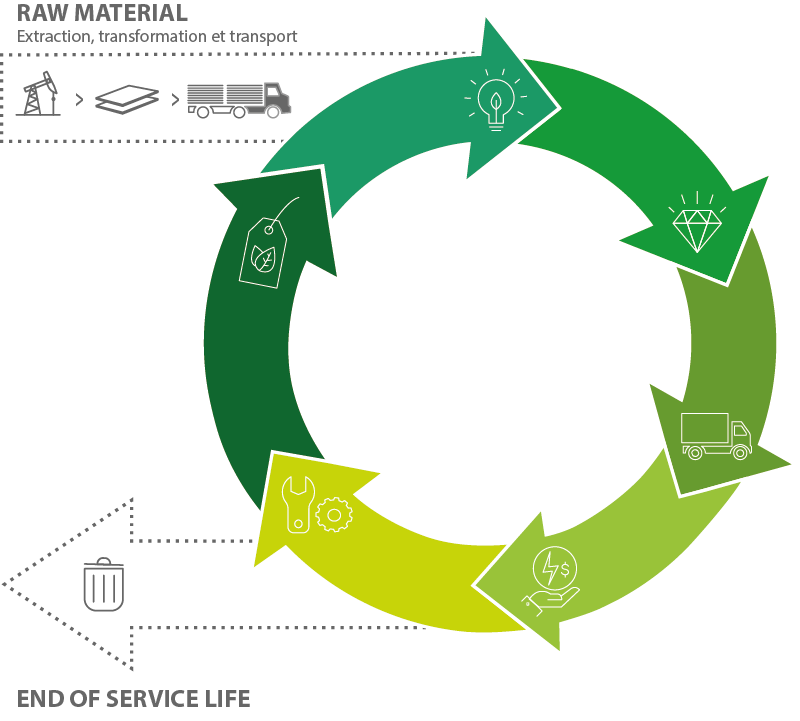

Conception

To encourage reuse, our vent fittings are designed to be as versatile as possible. We avoid "custom" designs to ensure that parts can be reused instead of becoming obsolete. More fragile components can also be replaced without having to dispose of the entire product.

Waste valorization

CTRI Industrial ecology project

We are proud participants in the industrial ecology pilot project supported by l’Espace d’accélération et de croissance de l’Abitibi-Témiscamingue and the Centre technologique des résidus industriels. The project consists of characterizing our production waste, analyzing its potential and finding innovative solutions to optimize it in order to reduce the carbon footprint of our plastic waste.

Ideation kit with Collectif Territoire

We have made ideation kits from our plastic scraps for the non-profit organization Collectif Territoire. These are used for co-creation workshops on land use planning with citizen groups.

Packaging

In order to minimize the waste associated with standard wooden packaging systems, our team has designed a steel shipping structure that promotes reuse and repair rather than single use. We offer a concrete solution to our clients to facilitate the management of their waste and, by the same token, help them improve their environmental balance.

We use a similar concept with some local suppliers. With the reusable steel packaging, we reduce the amount of waste and reduce our environmental footprint.

Energy

The use of plastic in mine ventilation promotes air movement with less resistance. In summary, this means that plastic ductwork will require 2 times less energy from your fans than steel ductwork, and 10 times less than flexible ductwork, to move the same air to your workers.

Reuse

Because of its material properties, our ventilation products are the only ones on the market that can be disassembled without compromising quality. One of our customers has been reusing the same ducts for almost 10 years, moving them from one gallery to another during the development phases.

Reconditioning

Our ventilation ducts get a second life at a lower cost. In the event of a breakage at our local customers, we are the only supplier to offer repair. We clean and replace the damaged parts, then reassemble and ship them back.

Mining projects often require unpredictable adjustments. That's why we can also remanufacture our ventilation ducts to smaller sizes to help put unused ducts into service.

- Eldorado Gold Québec have recycled, to date, more than 1100 pipes in their Lamaque mining project.

- Osisko Mining has recycled over 1800 pipes at their Windfall mine project.

Conception

To encourage reuse, our vent fittings are designed to be as versatile as possible. We avoid "custom" designs to ensure that parts can be reused instead of becoming obsolete. More fragile components can also be replaced without having to dispose of the entire product.